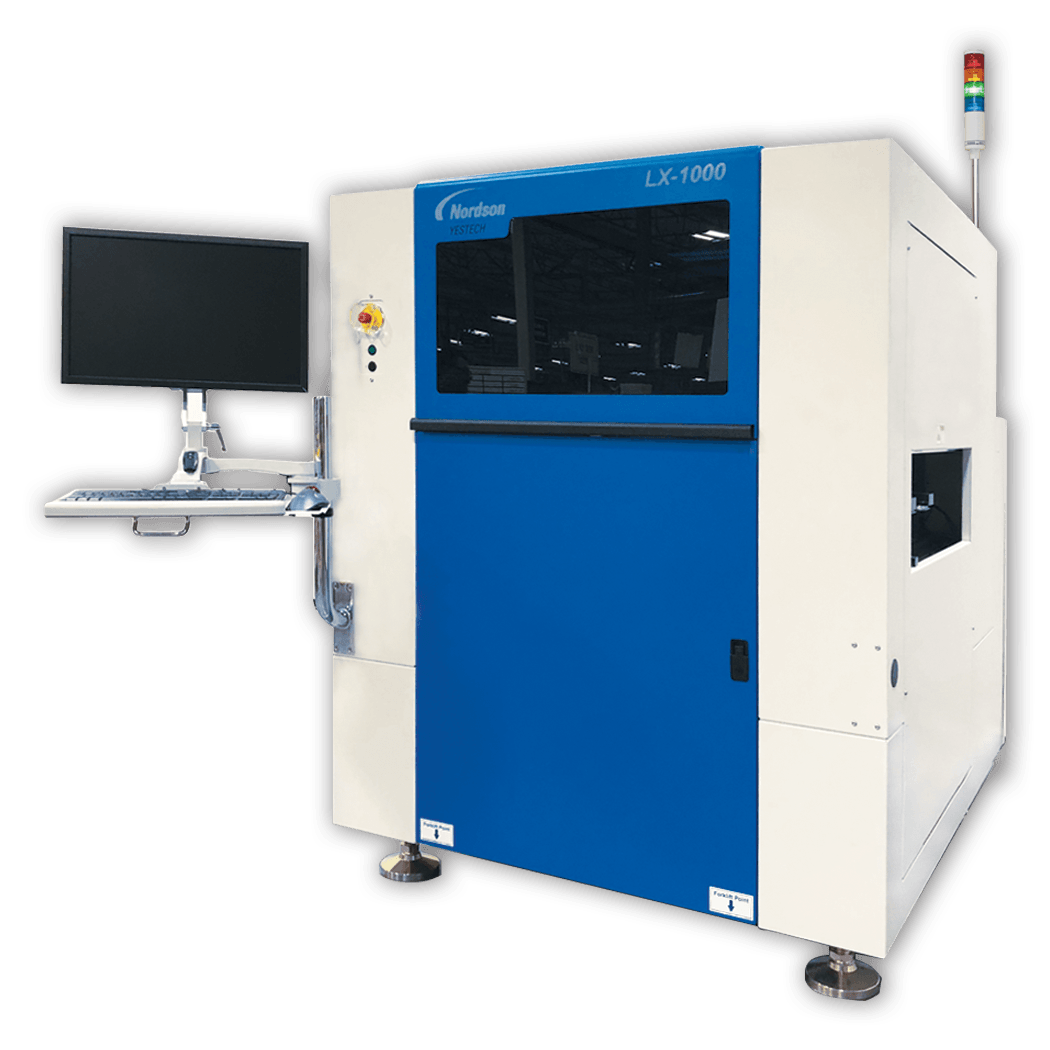

Nordson YESTECH LX-1000

In-line Large Area Opticall Inspection

Nordson YESTECH’s advanced multi-purpose, large area,

double-sided inspection system offers high speed PCB inspection

with exceptional defect coverage.

Download the YESTECH LX-1000 Datasheet

With dual sided top-down

and bottom up viewing sensors, the LX-1000 inspects solder

joints and verifies correct part assembly, enabling users to

improve quality and enhance yields.

Advanced 2D and 3D sensors and newly available image

processing technology integrates several techniques, including

fringe projection, color inspection, normalised correlation and

rule-based algorithms, to provide complete inspection metrology

with an unmatched low false failure rate.

Programming the LX-1000 is fast and intuitive. Operators

typically take less than 60 minutes to create a complete inspection

program including solder inspection. The LX-1000 utilises a

standard package library to simplify training and ensure program

portability across manufacturing lines.

The LX-1000 is highly effective for selective solder, post wave

and connector inspections. Off-line programming maximises

machine utilisation and real-time SPC monitoring provides a

valuable yield enhancement solution.

Features:

Single or dual sided imaging with full travel imaging sensors

630mm x 630mm large inspection area

Optional 3D and/or 2D automated inspection

Up to 100 mm clearance

Heavy duty conveyor options for samples to 15kg

High defect coverage / low false failure

MES / Industry 4.0 compatible

Automated Inspection for:

THT component and solder defects

SMT component presence and position

Wave / Selective solder joint inspection

Correct part / polarity

Configurable for automated conformal

coat inspection (ACI)

Find Out More

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

Cupio Ltd BeechwoodChineham Business ParkBasingstokeRG24 8WA

Contact Us

Tel: +44 (0)1256 262800

Site designed, built and powered by Halo Marketing Solutions.