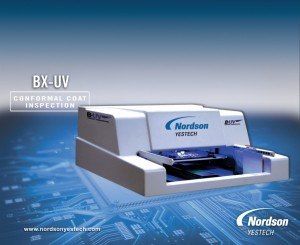

BX Benchtop Conformal Coat Inspection

The Nordson YESTECH BX-UV makes inspection of conformal coatings simple and convenient.

Conformal coatings used by electronic manufacturers contain UV indicators for the purpose of inspection. Since coatings are transparent, units must be viewed under black light in order to verify coverage and non-coverage. The Nordson YESTECH BX-UV makes inspection of conformal coatings simple and convenient by automating the inspection process for quality and consistency of coatings under UV lighting with the use of proprietary inspection algorithms.

Download the BX Conformal Coat Inspection Datasheet

Megapixel color imaging

Capture on the fly technology

1 top-down & 4 side angle cameras

Quick set-up

High speed

High defect coverage / low false failure rate

Optional 3D inspection

Programming the FX-940 AOI system is fast and intuitive. Operators typically take less than 30 minutes to create a complete inspection program including solder inspection. The FX-940 utilizes a standard package library to simplify training and ensure program portability across manufacturing lines.

Advanced Fusion Lighting and newly available 9 megapixel image processing technology integrates several techniques, including color inspection, normalized correlation and rule-based algorithms, to provide complete inspection coverage with an extremely low false failure rate.

Configurable for all line positions, the FX-940 automated optical inspection system is equally effective for paste, pre / post-reflow and final assembly inspection. Off-line programming maximizes machine utilization and real-time SPC monitoring provides a valuable yield enhancement solution.

Find Out More

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

Cupio Ltd BeechwoodChineham Business ParkBasingstokeRG24 8WA

Contact Us

Tel: +44 (0)1256 262800

Site designed, built and powered by Halo Marketing Solutions.