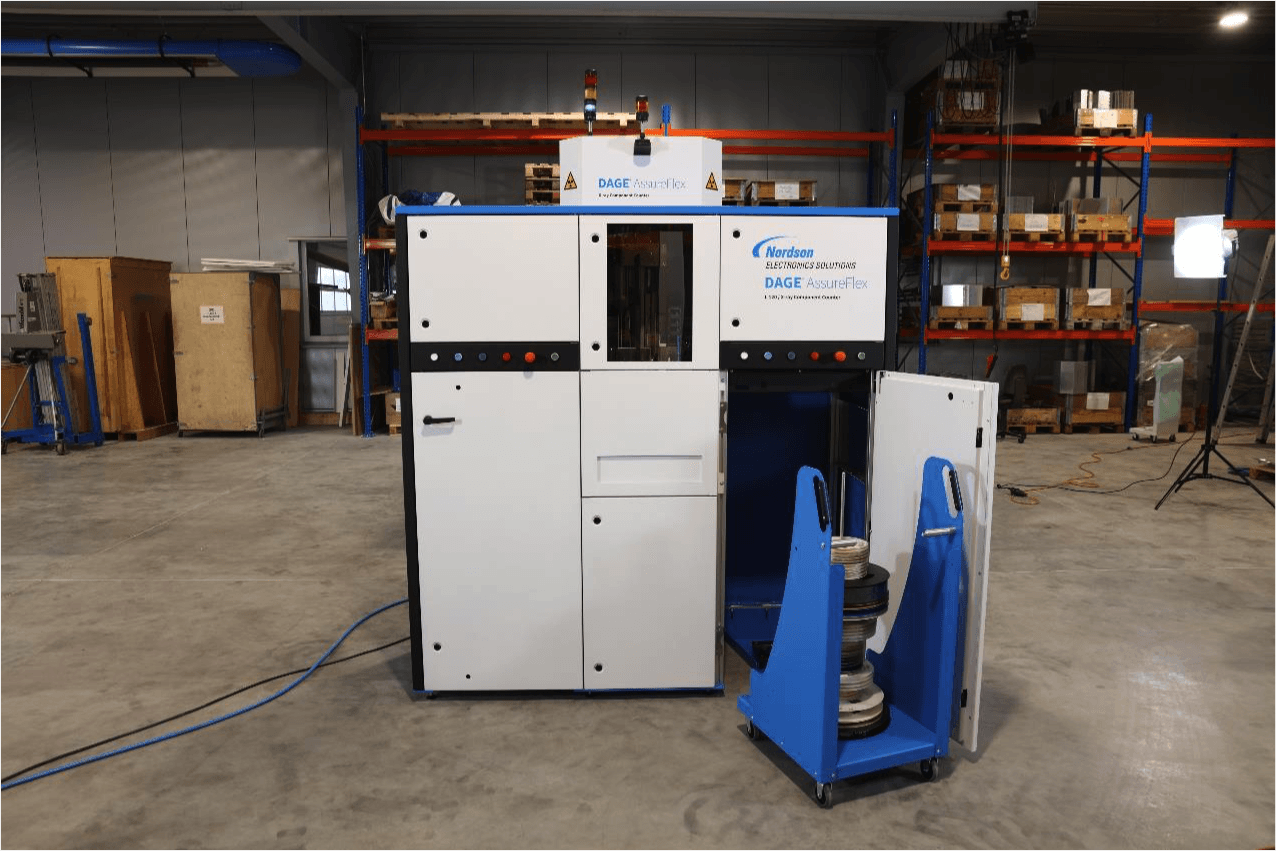

DAGE® Assure™ FLEX

-

More Intelligent

ButtonMonitor and control DAGE Assure Flex away from the line with the Assure Remote Control Station. Configure and monitor reel performance re-motely.

-

Simpler

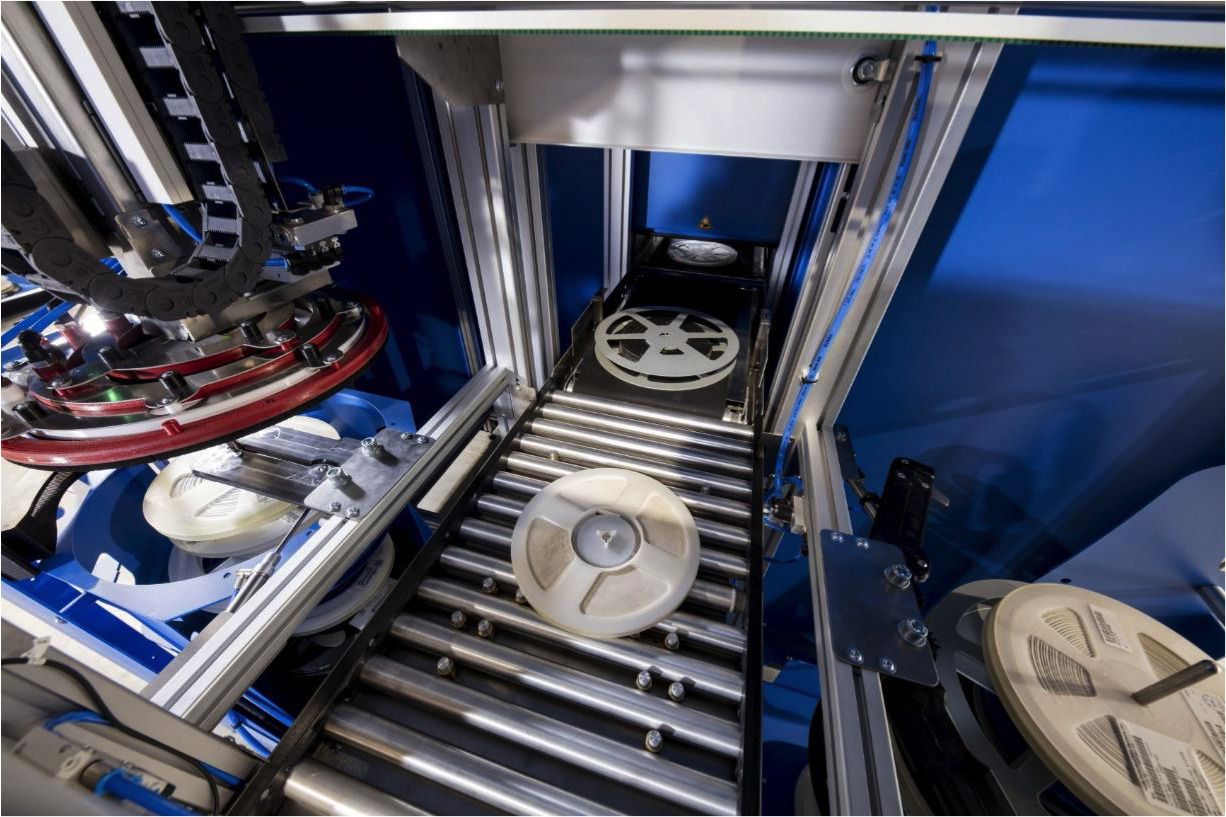

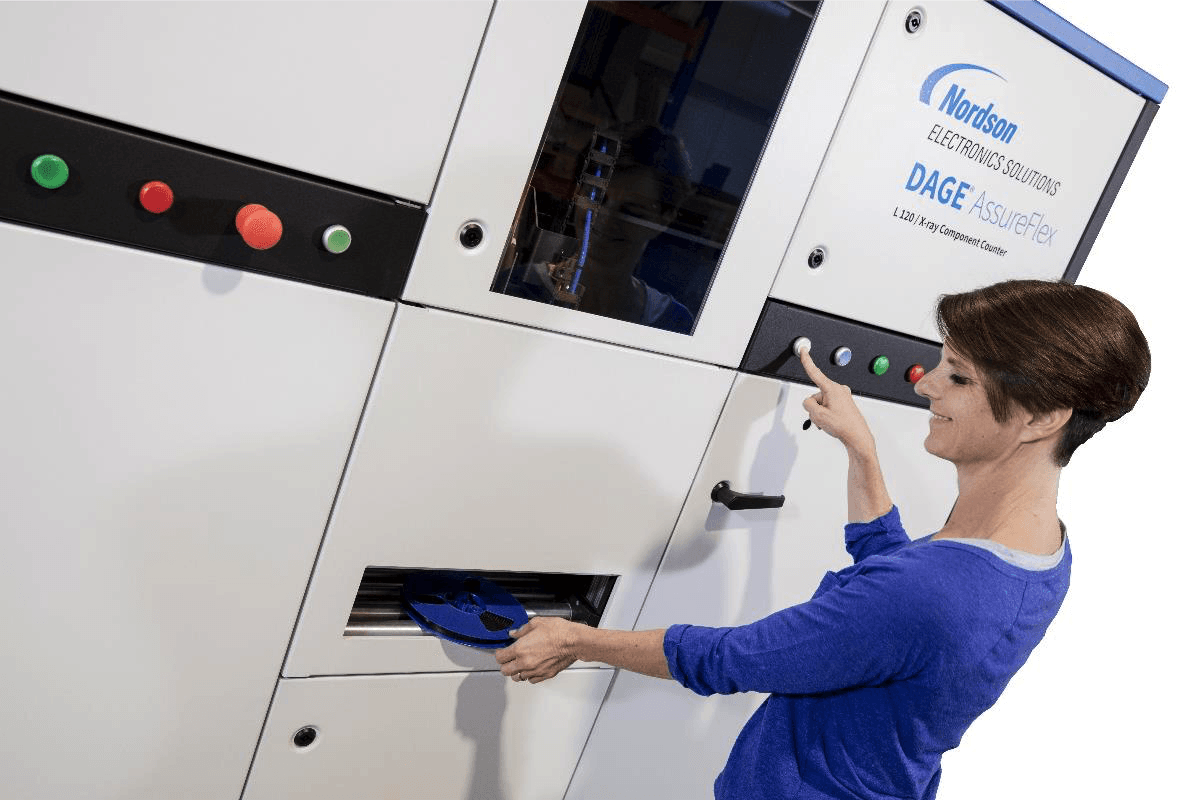

ButtonComplete operator free usage: reels are handled robotically from drop off through to collection.

New labels can be auto-matically applied with the Label Applicator Module, existing labels can also be updated with latest count.

-

Faster

ButtonHighest throughput: simply drop off the reel trolley and DAGE Assure Flex auto-matically takes care of the count. Urgent reels may be counted on demand with the high priority load slot.

-

Complete Trust

ButtonAutomatically sort good reels and those requiring additional checking into different output trolleys.

-

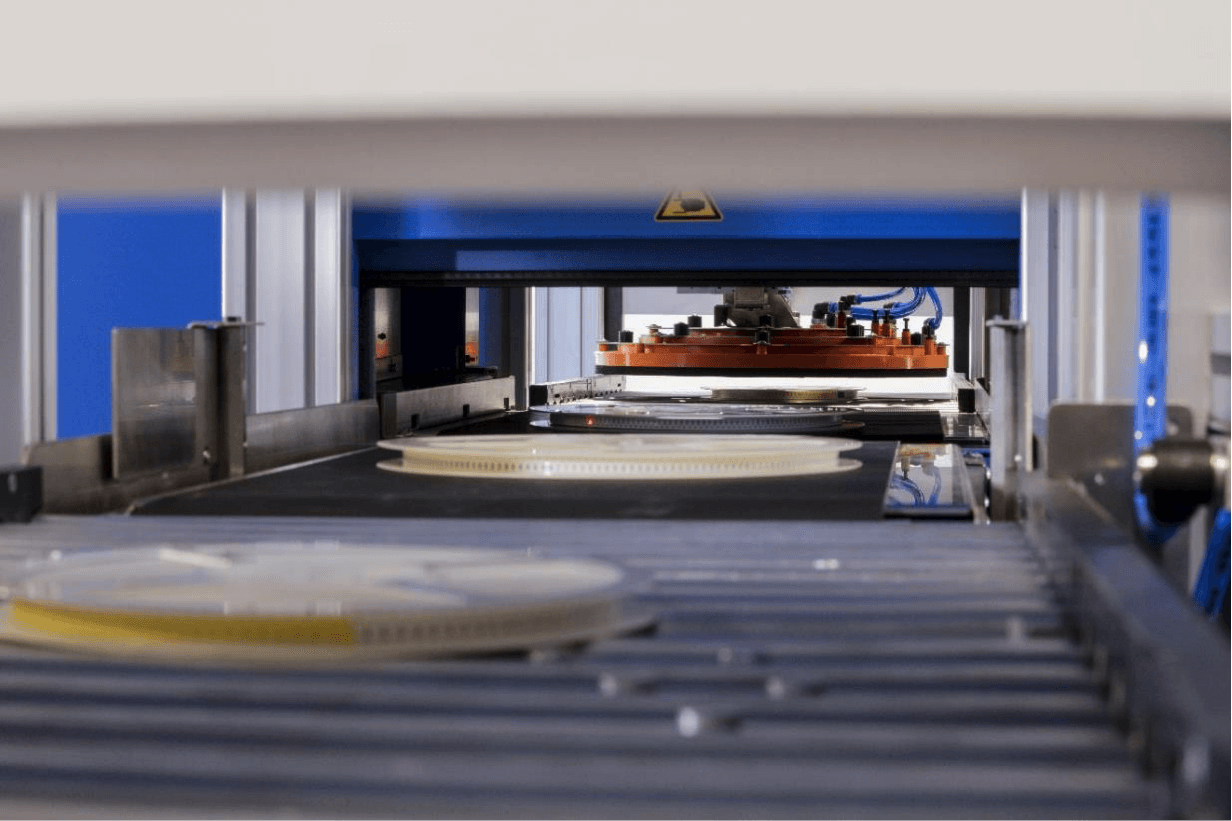

Fully Automated Storage Solution

ButtonDAGE Assure Flex has an integrated conveyor which can feed into a range of existing, high capacity storage system

solutions. Reels are fed through on conveyor for a fast, automatic count. Integration to new storage systems is fast and easy with DAGE Assure Flex’s robust and well documented software inter-faces. Build DAGE Assure Flex into your automatic storage system today, or as your needs change in the future.

Contact Us

We will get back to you as soon as possible

Please try again later

Cupio Ltd BeechwoodChineham Business ParkBasingstokeRG24 8WA

Contact Us

Tel: +44 (0)1256 262800

Site designed, built and powered by Halo Marketing Solutions.