As a family-run company with nearly fifty years’ expertise, FermionX offers both contract electronic manufacturing and design for manufacture services. They tailor their solutions to customers ranging from established companies seeking to outsource their work, to innovative product brands who need their industry expertise. Long experience with their own two international brands gives them deep insight into the pressures on product manufacturers endeavouring to meet their customers’ requirements.

Their contract manufacturing services include supply chain management, PCB assembly, and box build. All services are operated with a rigorous quality control regime meeting ISO 9001:2015, ISO 14001:2015, RoHS and CE compliance.

An ever-increasing demand for inspection quality

The electronics manufacturing industry has always required X-ray testing of assembled PCBs, and, until recently, FermionX outsourced this. However, the company has been growing, and is now branching into military and defence – and customers in these markets only use suppliers with in-house X-ray inspection capability, because they cannot risk deploying products that have not been fully inspected.

Meanwhile, as components continue to shrink, manufacturing problems will become impossible to spot with the naked eye, so even companies working in less unforgiving environments are increasingly seeking the peace of mind that X-ray inspection provides. FermionX regards X-ray inspection as the only technology that can assure their end users of their quality and compliance with industry standards. Also, bringing the service in house creates cost savings that can be passed on to customers – a crucial benefit in the current economic climate.

The right choices of system and supplier

Having identified the need for in house X-ray inspection capability, FermionX had to decide on which system would suit them best, and who best to purchase it from. From the outset, Cupio – with their Nordson product lineup - appeared as the most likely choice for supplier, as they had previously delivered a Nordson YESTECH FX-940 automated optical inspection (AOI); the experience had turned out well in terms of both Cupio’s support and Nordson’s product.

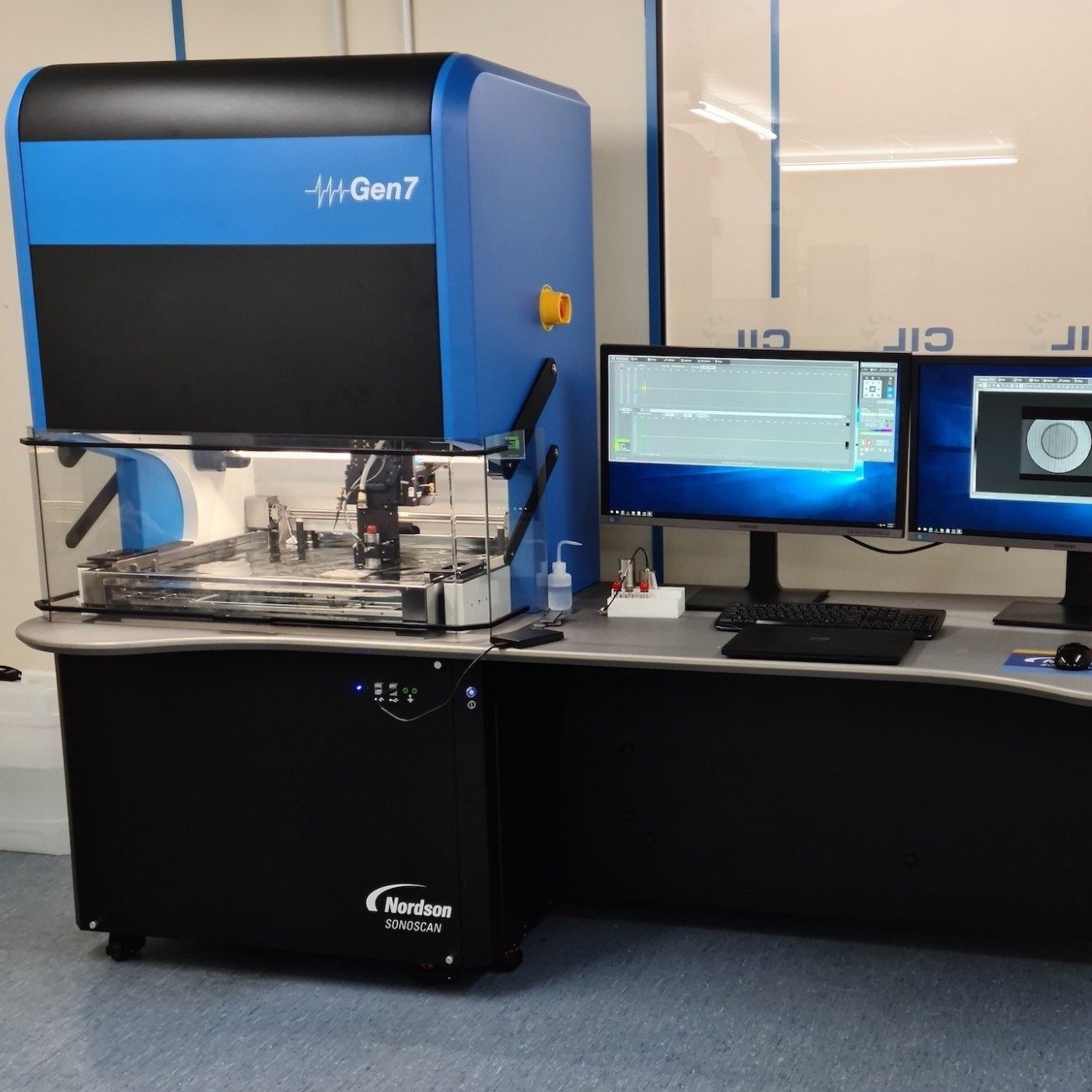

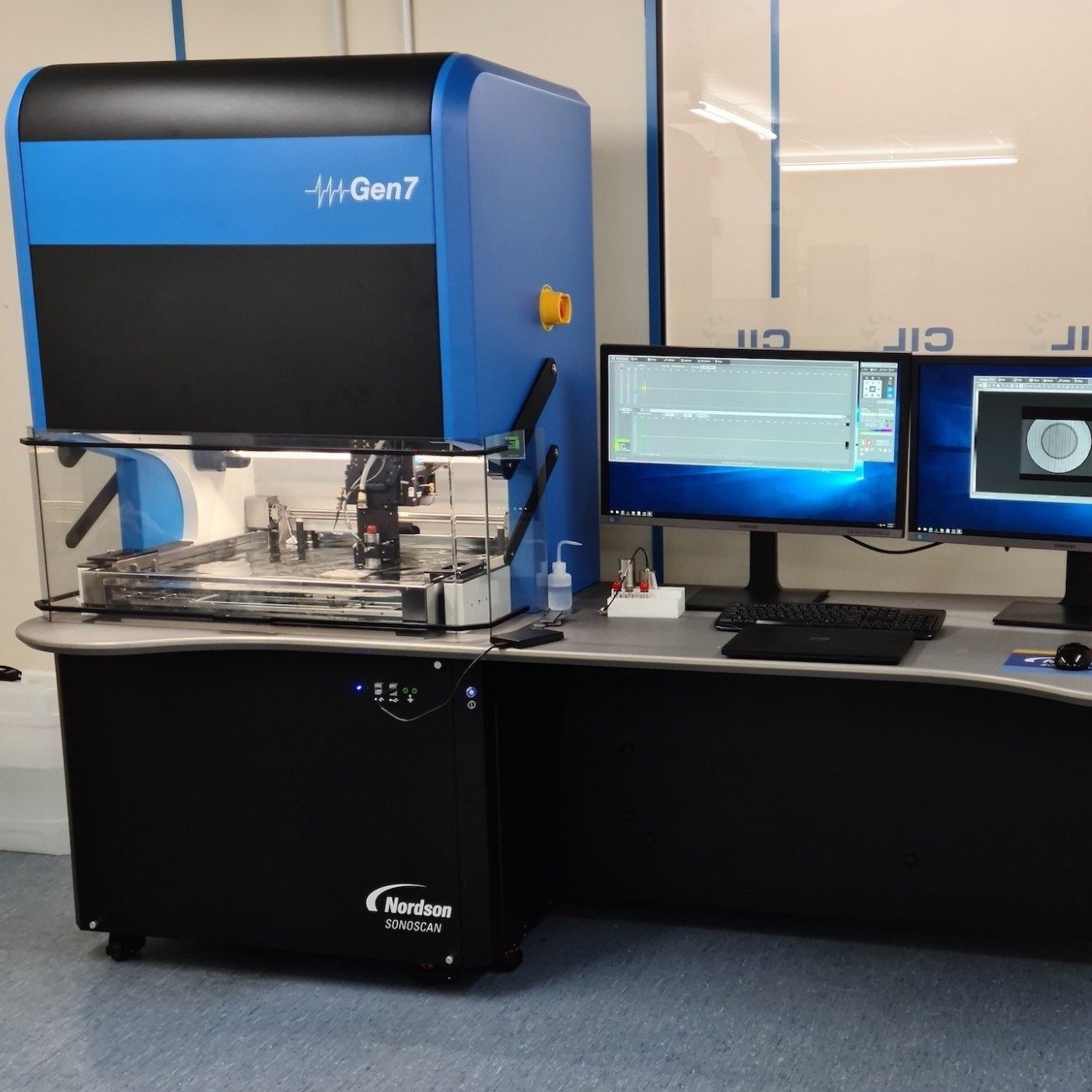

Accordingly, they chose the Nordson DAGE Quadra 3, which is ideal for high quality X-ray inspection in production line quality control. They liked the Quadra’s ability to change viewing angles and see every detail from all sides at high magnification, without having to rotate the PCB under inspection. Being able to view BGA pads from side angles as well as from above means they can check for interfacial faults, or if the ball is not touching the pad or the board.

The software allows for void checking, giving not only total void percentage, but also roundness, diameter and largest single void. Additionally, the Quadra’s X-ray source uses proprietary filament free technology; this requires no regular maintenance or filament changes, while the inspection imagery remains clear and repeatable.

This assures FermionX and their customers that their boards are compliant with standards such as IPC-A-610G.

From enquiry to installation and training

“We have had nothing but positive experiences with Cupio throughout the whole process from enquiry to installation and training” commented Samantha Lane, HR, HSE & Business Process Improvements Manager at FermionX, “After our initial enquiry, we were invited to Cupio’s Basingstoke facility to see a live demo of the machine – we even inspected one of our own boards!

“Seeing the machine gave us a far better understanding of what we wanted and needed, and allowed us to make an informed choice when deciding on which company and machine to proceed with.

“Following our purchase, Cupio was always on hand to answer the pre-installation questions – and there were a lot!

“When the machine arrived, it was installed with no issues, making the process as easy and stress free as it could be. Cupio’s trainer Ben Seviour joined us for the installation and training. He has a wealth of knowledge which is evident when he is describing what the machine is doing and how to operate it. His training was well received, and gave our staff the skills and knowledge needed to start operating the machine as quickly as possible.”

Integrating the Quadra into FermionX’s production process and QA program

FermionX has now added the Quadra’s X-ray inspection capability to the Nordson YESTECH FX-940 AOI and many other items of inspection and QA equipment. They are loading all their ‘first offs’ into the machine as it provides a quick and accurate way to identify any fine voiding in the BGA, and if it is interfacial.

If they identify voids in the BGA, they can slightly increase the time above liquids during reflow by a few seconds, allowing the gas to escape and reduce future voids. This method allows them to instantly report to the Surface Mount team if there are any faults, and prevent the whole batch from running incorrectly.

As well as being an important pass/fail check for individual boards, voiding is also a good indicator of the overall production quality.

Exploiting the Quadra’s full potential

While using the Quadra to raise production efficiency and make quality improvements, FermionX also sees it as a tool for component failure analysis, reducing the amount of unnecessary repair. Time saved in inspection allows their hand assembly team to build a batch of boards more efficiently and the surface mount team to run the machines for longer.

FermionX will also offer the Quadra’s X-ray inspection capability to OEMs seeking to outsource this activity. The machine can provide them with video reports giving a complete view of all boards inspected. Equally, FermionX’s customers can utilise X-ray inspection when running a first time design, or if they experience repeated issues in their manufacturing process.

“Although our quality has always been very high, the Quadra reduces the likelihood of returns or failures in the field, by checking our boards prior to despatch” Samantha Lane commented, “Should the worst happen, we will be able to investigate the boards as soon as we receive them. This will significantly reduce the turnaround time and gets the products back to our customers quickly – complete with a report to explain the issues and how they were rectified, to give them peace of mind.”

Site designed, built and powered by Halo Marketing Solutions.