Jaltek supports products throughout their lifecycle, offering a single service or complete solution with over 35 years’experience in providing solutions for a range of industries, including those requiring systems for harsh and safety-critical environments.

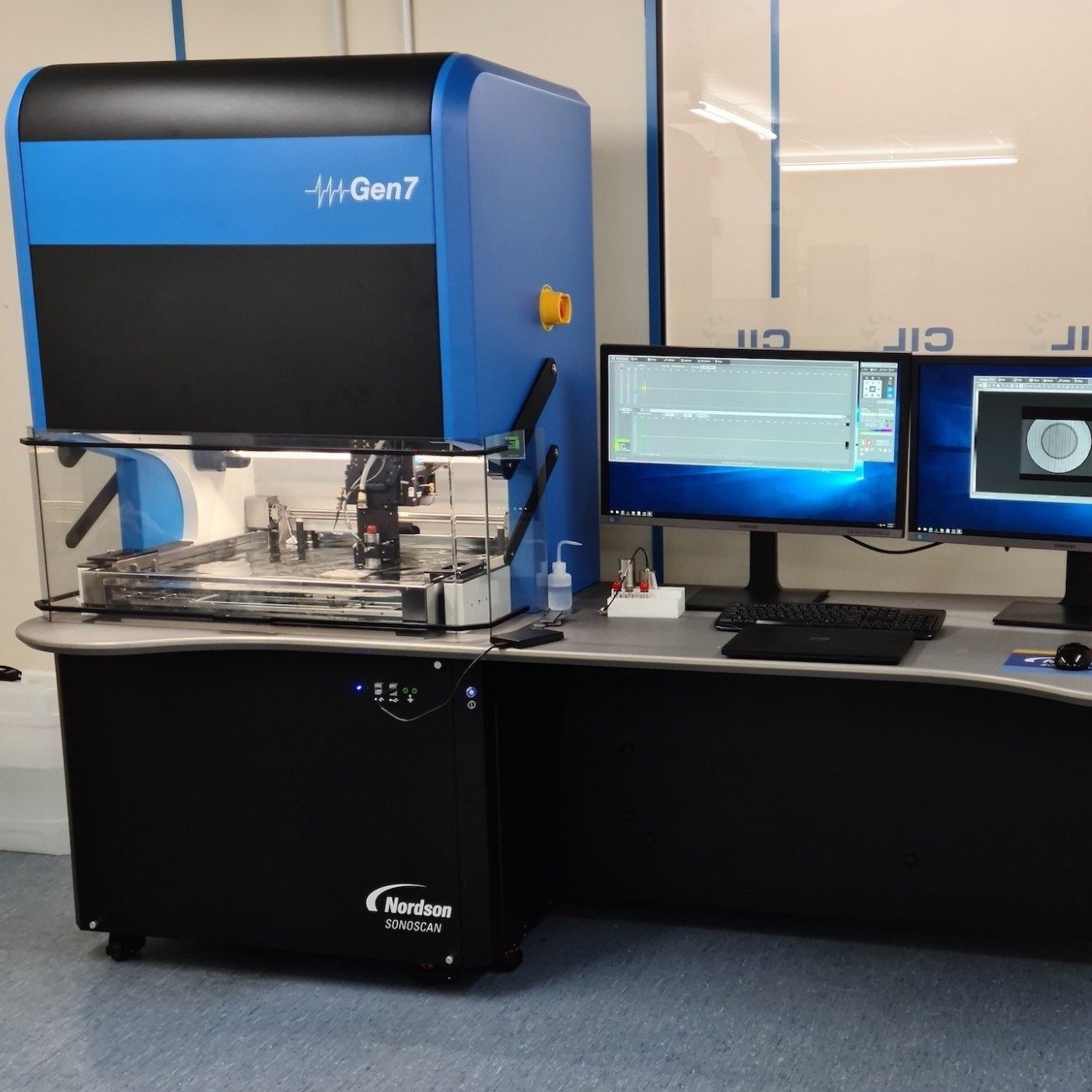

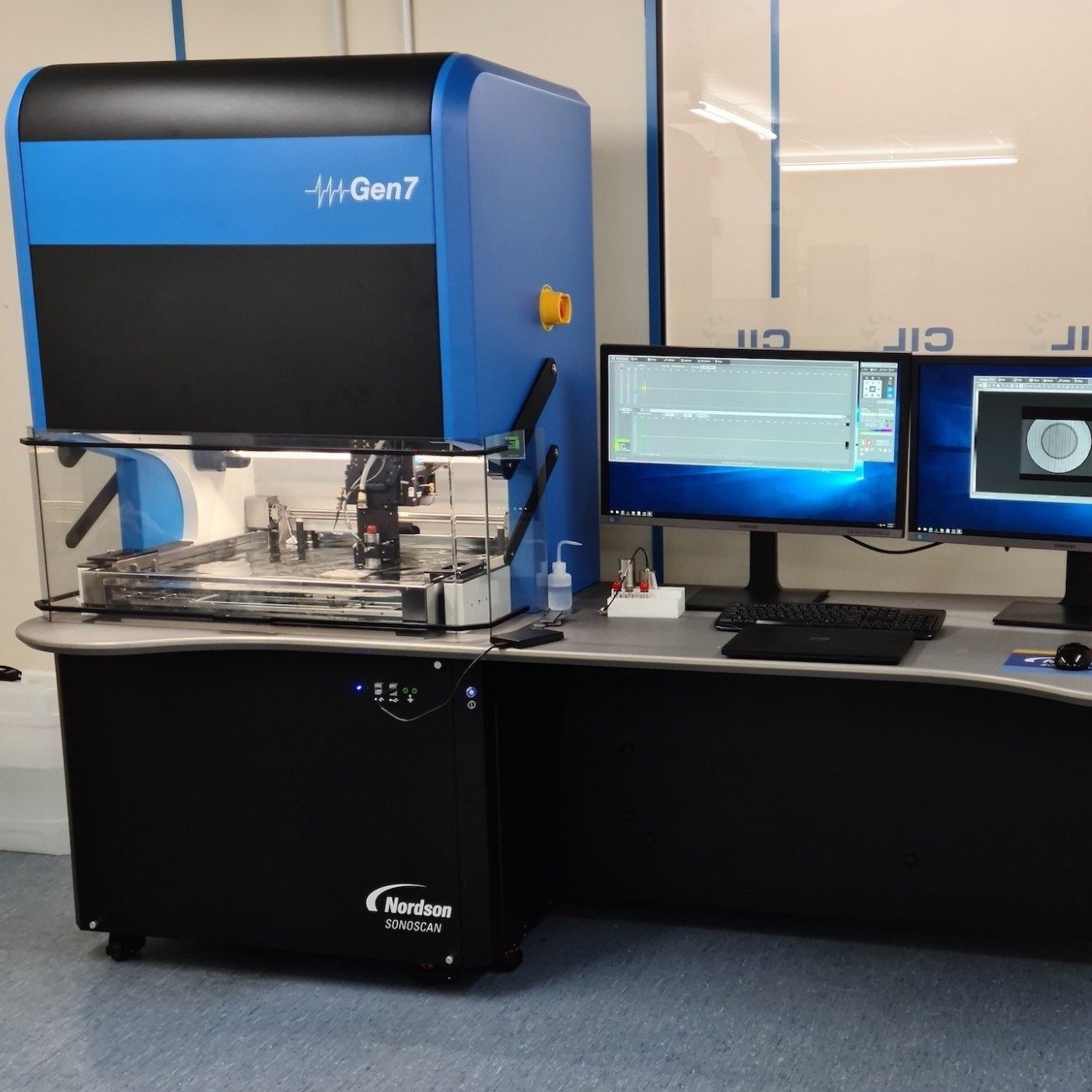

Jaltek’s exceptionally high production quality is due in part to their X-ray inspection capability. However, their incumbent system had been in service for several years, so the company decided it could accelerate their Industry 4.0 journey by adopting the latest inspection technology advances. Accordingly, in July they took the important step of purchasing a Nordson Quadra 5 X-ray inspection system from Cupio Ltd, for assembled PCB inspection. This particular state of the art model allowed the company to further enhance their level of automation and production line integration, while providing higher resolution scanning and more functionality. Improved efficiency and faster throughput were considered essential to support the increasing volume of business.

Fulfilling the requirements for X-ray inspection

Jaltek needed an X-ray inspection system to complement their automated optical inspection (AOI) machine. The AOI performs a full board scan, while the X-ray inspection system checks issues such as voiding under a BGA, which AOI cannot detect. The need for X-ray inspection of increasingly higher resolution has grown as components, and the spaces between them, have steadily shrunk in size. This is because OEMs are under constant pressure to introduce ever smaller, yet more highly functional products - this is especially typical of the automotive sector.

Jaltek considers this inspection approach to be valuable for development as well as production. During prototyping, this complete inspection capability allows them to check every process step, so quality is built into the design. The same detailed inspection strategy can then be applied during production.

X-ray inspection is also used to service customer requests for inspection reports and images, which can be as detailed as specifying an individual component viewed from a particular angle.

During discussions about a possible machine replacement, Jaltek received several recommendations to consider Nordson products; they have long been well-known in the industry - originally under the Dage name, before coming under the Nordson banner. Accordingly, Paul Livingstone, Jaltek’s IT Infrastructure and Support Technician, alongside colleagues Chris Cochrane, Senior Process Engineer, and Simon Lee, Quality Manager, started their research. They soon identified Cupio as a primary Nordson supplier and following an initial telephone conversation and receipt of relevant machine information, Paul visited Cupio’s demonstration area in Basingstoke.

After a couple of demonstrations at Cupio, and a viewing of a system in Nordson’s Aylesbury manufacturing facility, Jaltek decided that the Quadra 5 was best aligned with their current and future plans.

As well as its superior image quality, Jaltek particularly valued the system’s automated ‘step and repeat’ capability. The company often produces PCBs comprising 20 boards in one panel, with components needing inspection in each board; previously this had to be manually driven. By contrast, the Quadra 5 features AIR automated inspection routines which can be programmed once to step and repeat through each of the 20 boards in the panel automatically. This considerably reduces production time compared with the earlier manual approach.

The Quadra 5 has two display screens, so an operator can use one screen for setting up a panel of boards and initiating the inspection routine, while also reviewing a previous batch on the second screen.

Jaltek is keen to explore other features of Quadra 5, particularly its CT scan capability. This uses X-Plane to build X-Ray 3D images comprising up to 1000 distinct slices or image planes of the component being inspected. A slice will remove obstructions above and below the plane of focus so that only the regions of interest remain. This means that if a board is returned, for example on an RMA, with an indeterminate fault, X-Plane would allow the manufacturer to pinpoint it.

“We’ve only had the system for a couple of weeks, so it is still very new, but we have been extremely impressed with Cupio’s support from the outset” commented Paul Livingstone, “We started discussions about a year ago and CEO Andy Bonner wasted no time in setting up a demonstration for us. Since then, he and Ben Seviour, who are very knowledgeable about the machine, have been consistently helpful in explaining all its capabilities.

“I was particularly impressed by their response when a fault appeared on our machine soon after delivery; An extremely rare event, yet Andy was on site within two hours to fix it. They are just a phone call away and we also have the ability to share screens over a secure line and communicate in real time via remote access.

“After completing installation and commissioning, Ben has been providing ongoing training for our existing and new operators, and Cupio is always offering to come and help us if we need it. Clearly, they see success as being as essential to them as it is to us.”

The path to full integration

For Jaltek, ever-increasing integration into the production line and its equipment is another important goal. The Quadra 5 is already on the factory network, so any images stored on the machine can be accessed immediately by remote users across the network. The machine is also integrated into the company’s manufacturing execution system (MES), FactoryLogix, supplied by Aegis Software. This allows operators to view their work instructions and plan their upcoming actions.

However, Jaltek plans to further evolve this integration by using the MES to exchange XML or other format data files with other production line equipment without need for doing so manually. Fault data can be recorded and saved on the system for easy access by appropriate personnel.

This helps with traceability; Jaltek traces panels and boards using serial numbers, and this should propagate through the entire process. All authorised users should be able to view board data from anywhere, at any process stage, see status and any fault information, and view X-ray images. These images can be stored on network drives rather than using capacity on the local machine drive. Reports for customers will also be generated more quickly and easily.

Into the future: realising the potential of Industry 4.0

Steve Pittom, Jaltek’s CEO, rounded up the company’s recent acquisition by saying, “The Quadra 5 is an important investment, and essential to keeping a competitive edge in the industry; it represents a further move towards automation. We are also investigating cobots and various other ideas, it is an exciting time for manufacturing.

“We will always aim to work smarter and more efficiently with the resources we already have. However, we need Industry 4.0 technology to ensure our production throughput and customer responsiveness is even slicker and faster, while continuing to build on our high quality standards. That's absolutely key to us, especially considering the sectors that we work with.

“The Quadra 5 will play a big part in realising our ambitions, and we hope to continue our relationship with Cupio, and benefit from their years of inspection experience.”

Site designed, built and powered by Halo Marketing Solutions.